Liquid Nitriding Process

Basic Process Steps for Liquid Nitriding:

| CLIN Process Steps |

Scope |

Description |

| Degreasing/Rinsing |

Remove oils, and other particulates from the surfaces of the parts |

|

| Preheating |

Maintain a stable temperature in the nitrocarburizing melt |

|

| Nitrocarburizing |

Nitride layer formation on component surface. Using HEF’s ARCOR® and MELONITE® & TUFFTRIDE® / (TENIFER®) Nitriding salts |

The hard nitride layer provides wear resistance. The diffusion region underneath the nitride layer provides improved fatigue life |

| Oxidizing* |

Oxide layer formation on component surface. Using HEF’s Oxynit® and other trademarked Oxidizing salts |

Oxynit® is a post-nitrocarburizing molten salt bath treatment that provides added corrosion protection by oxidizing the porous zone of the iron nitride compound layer into stable iron oxides (Fe3O4) – also called magnetite. Oxide layer also provides a black aesthetic appearance. |

| Cooling/Cleaning |

Remove salt from the surface of the parts |

|

| Mechanical finishing* |

Smooth surface, low roughness (no lower than before treatment), friction properties |

HEF expertise:

Blast finishing

Mass finishing

Centerless polishing |

| Surface Impregnation* |

Additional corrosion resistance;

improved run-in behavior;

deep-black appearance |

HEF impregnation using:

Corolac® (dry appearance)

Corofluide® (oily appearance)

|

| *optional |

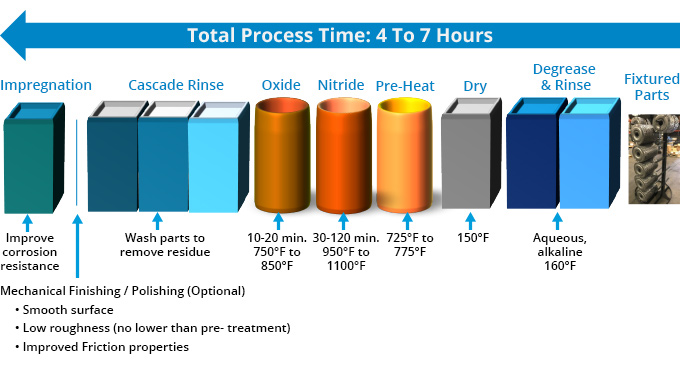

The LN process is carried out in equipment manufactured by HEF and customized to the nature of the applications under consideration – the size and shape of components to be nitrided; the throughput rate required; process steps required to achieve the desired nitriding specifications; and environmental considerations. A schematic view of a typical ARCOR® process line is shown below:

These CLIN process lines can be fully/partially enclosed or have an open configuration as shown below: